GEAR

We produce all of our gears in PWT-Netherlands which is leader in gear industries for more than 142 years

PINION

Our pinions and pinion shafts which are produced in PWT-Netherlands provide the highest quality around the world

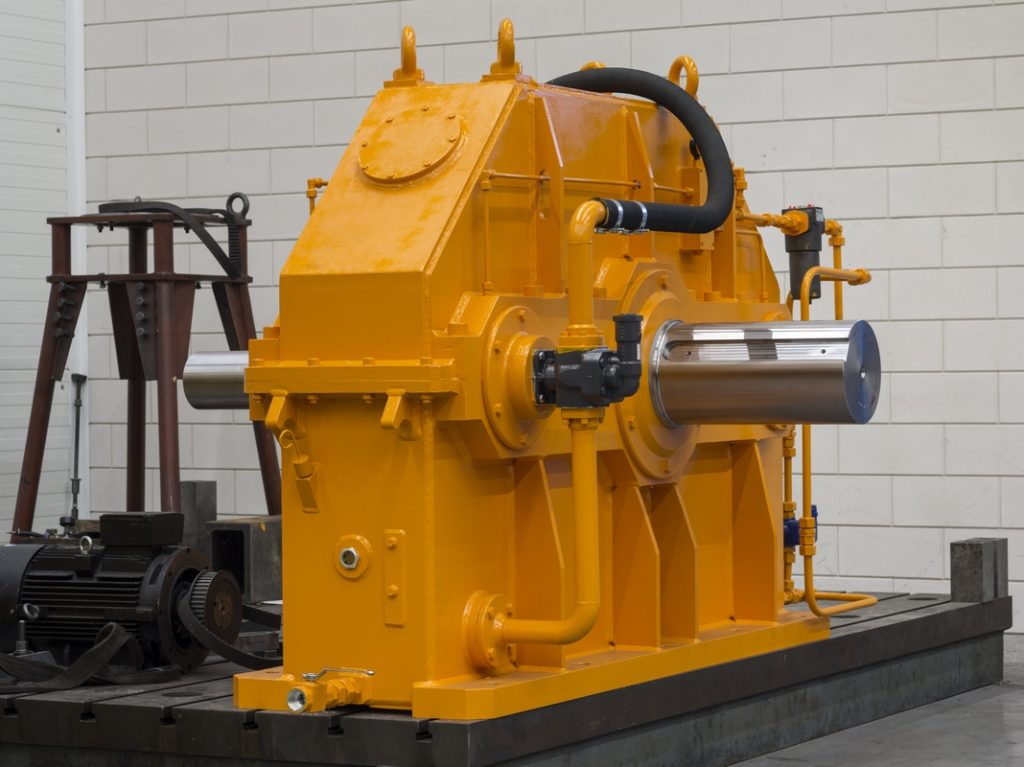

GEARBOX

We produce customized special drive system according to your requirement in Pwt Bierens which has over ten thousand gearboxes in history

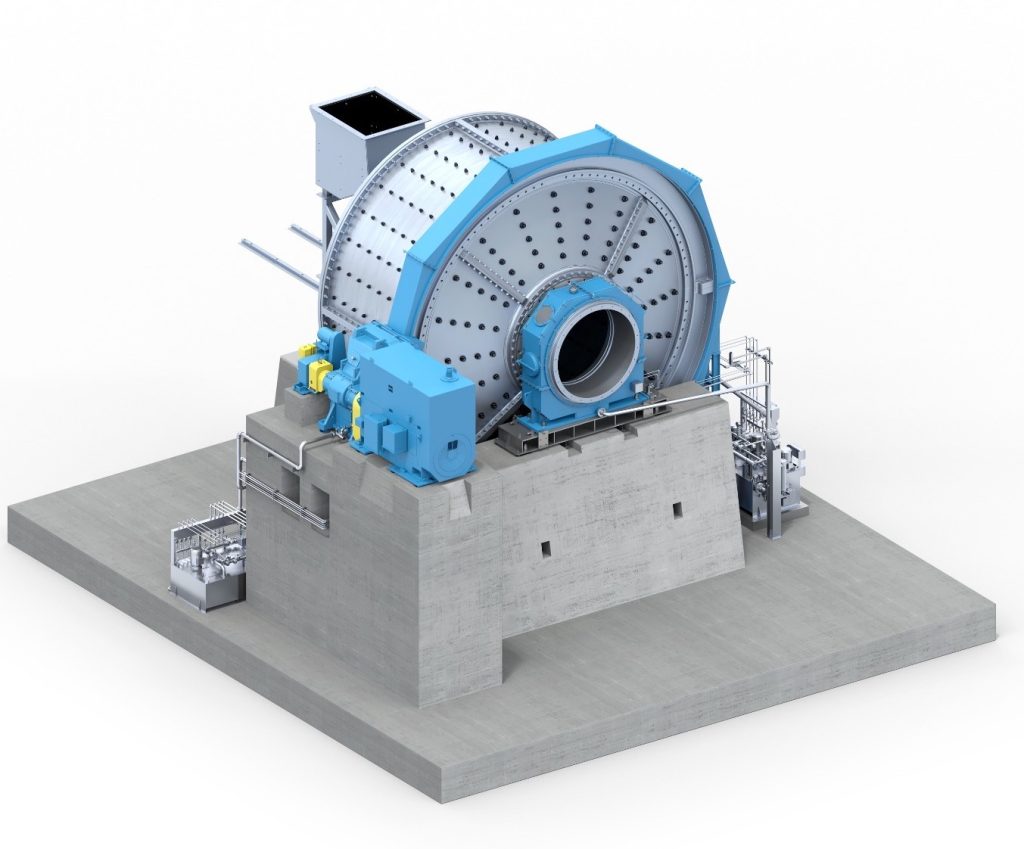

GRINDING MILL

Famous and leader Mill designer are engaged in our Grinding engineering department to approach the best lifetime in parts and lowest shot-down by reduction in maintenance time

CRUSHING

Our cone crusher is produce by considering higher performing in additionally with lowest repair and maintenance

GEAR

Girth Gears / Ring Gears

We produce all of our gears in Pwt-Netherlands ,the leader in gear industries for more than 142 years. Pwt is equipped with modern facilities such as gear cutter by capability to produce gears up to 30000 min diameter and and maximum weight 500 tons by using the Carbide hobbing in fully generating method up to module 60 .

Furthermore, unique multifunctional PowerTec13000 machine with workplace dimensions 13000 mm width, 26000 mm length and 7000 mm height provide maximum capability of machining rotary parts such as Mill Shell up to Diameter 14000 mm and Length 25000 mm.

PINION

Pinions / pinion-shafts

Our pinions and pinion shafts which are produced in

Pwt-Netherlands provide quality better than 14 according to AGMA 2000-A88 compared to max Q10 for normal hobbed pinions.

The combination of high quality carbide hobbing of the gears and the teeth-grinding of the pinions assures a contact-pattern about 90 – 95% which is amazing in gear production industry around the world.

No expensive running in using special lubricants during start up is the other benefit of our delivered pinions.

Increasing your production through start up with 100% instantly after installation is the one of most advantage of Pwt gears.

Our forged steel case hardened (carburized) pinions which produce in vacuum degassed will provide extreme high hardness

(62 Rockwell C) and very low wear in lifetime, this benefit lets the mining industries to continue their production lines without unplanned shutdown for changing the pinions.

GEARBOX

Special drive system

We produce customized special drive system according to your requirement in Pwt Bierens which has over ten thousand gearboxes in history.

We are with you from start to finish, including the (detailed) drawings, the parts list and the instruction manuals according to your plant situation, it is only needed to send us your inquiry include the requested data sheet and then we are being in touch with you to approach your desired design.

Repair & Renew

In special case that customer has limitation in arrangement or in the case which exist gearbox is old and out of recent production , we are ready to help you and get complete responsibility to repair or renew your existing gearbox (regardless of the manufacturer) according to last design and standard in the world.

GRINDING MILL

SAG Mill and Ball Mill

Famous and leader Mill designer are engaged in our Grinding engineering department to approach the best lifetime in parts and lowest shot-down by reduction in maintenance time, which are critical and expense in mining industries. Our Mill Shells produce in famous European factories.

Our SAG and AG Mills provide best grinding of the mining ores with the lowest power consumptions.

Our Mill design support your requirement to reduce your cost and get best solution for combination of crushing and screening equipment in unique SAG/AG Mill.

The ores inside the mill are lifted by the rotary motion and fall down by their gravity and are grinded in this method.

In some case which material is hard or in order to speed up the grinding process, grinding media will be added to the mill, this new part help process to increase breaking in material. The throughput rate could be controlled by balls in SAG mills.

Why our Mill is the best

We produce every main parts in specialized factory. The mill heads are casting in the Germany foundry and shell will be fabricated in Italy under accurate quality control of our QC department which follow the latest standards, the result will be best operating life time for complete mill.

All rotating body and parts of Mill calculate and check by finite element analysis, the main bearing fluid film analysis, torsional analysis and mill dynamic modal analysis even system stiffness analysis.

CRUSHING

Cone Crusher

Our cone crusher produce by considering higher performing in additionally with lowest repair and maintenance, it thanks to the European design and quality.